I've seen a couple posts lately about stuck/stripped air mix screws and since I was one of them, wanted to share how I got mine out. Trying to be helpful and all....

So, a couple days ago I managed to strip the hell out of my air mixture screw when attempting to correct backfire issues. That sucked, but one of the members here,- gdrseeker- was kind enough to send me an unused air mix screw to replace it with. I went ahead and ordered Lancer's jet kit, figuring I might as well do everyhting while I'm busy fixing the screw. I got the carb out fine, but...

PROBLEM: the stupid screw was really stripped, I could not get traction at ALL. Why that thing is made of brass I have no idea. It felt like I had pushed on it too hard and maybe bent some threads or something. Regardless, my first thought was to spray it with PB Blaster, let it soak, the tap a screw driver into it with a hammer to see if I could get it turning. Then I remembered that too much pressure was what started this mess to begin with, so I nixed that idea. I did hit it with some PB Blaster, though.

Well, I've turned wrenches for fun for a while, so this is not my first stuck screw. Thought about using a torch, then I thought about the gasoline and maybe catching myself on fire- no go. I tried my set of Probit Extractors- which normally work like a champ- but they would not reach the screw. I considered grinding down the metal around the screw to get access, but reserved that as a last resort.

I was finally faced with saying screw it (haha) and buying a new carb, but that was not financially reasonable. I would take it to a machine shop, but I don't want to be THAT guy, and even a machinist could jack it up good. I prefer to break my own stuff. All the normal options were eliminated down to trying to drill it out. So I did, and it worked.

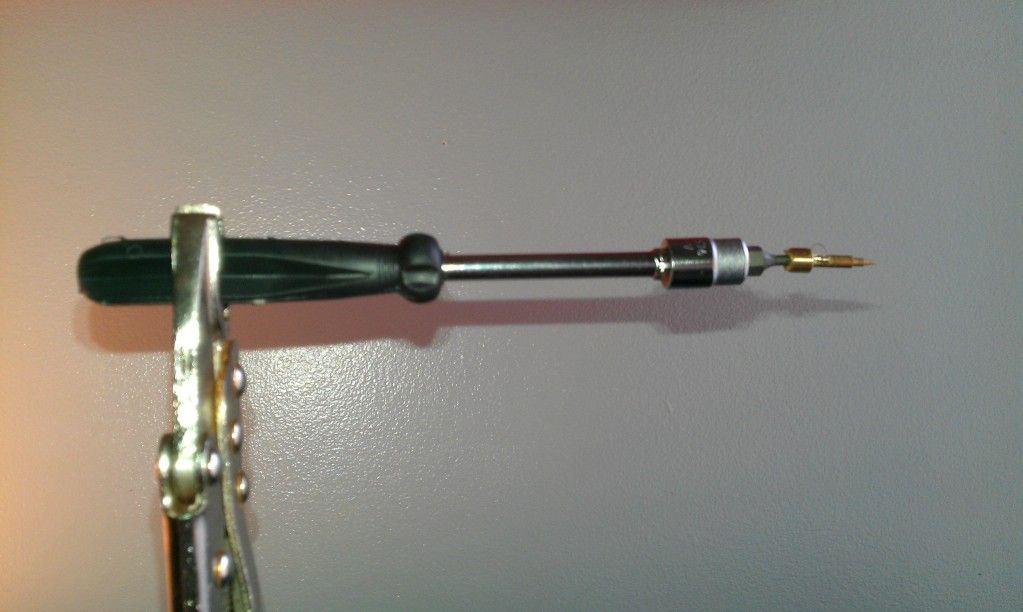

First, I used a power drill and a 1/16th kobalt bit to start a pilot hole in the center of the screw. This was pretty shallow, but I then stepped up to a 5/64 drill bit and made about a quarter-inch deep hole . So far, so good. Then, I used a T8 torx bit (quarter-inch drive) and very carefully used a hammer to tap it securely into place.

MAKE SURE YOU DRILL AND TAP THE BIT IN STRAIGHT. I did not have a ratchet that size, so I used a quarter-inch drive screwdriver and clamped onto the handle with a pair of vice grips for leverage

(You WILL need to do this. Trying to crank it by hand without the added leverage is NOT going to work.) Then I said a little prayer, applied gentle, steady pressure and... it came out like a champ. Hopefully the pictures post below.