Pol,

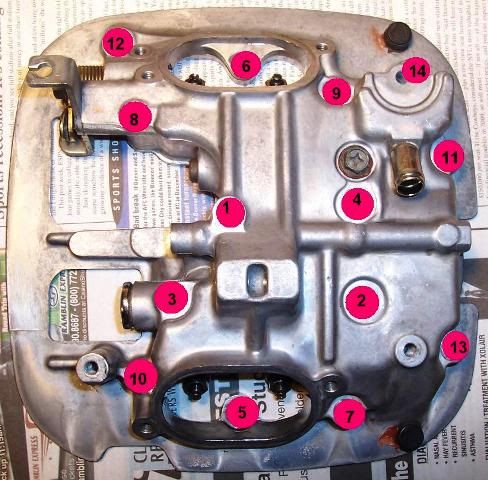

Well, the 4 topmost head bolts are easy - it's a simple criss-cross pattern.

If you are referring to the head

cover bolts, you are right, the FSM does not specifically call out a certain pattern. I threw one out there a few years ago and nobody here has crapped on it (yet):

You will find that location #12 presents an elevated challenge. That is because that hole is used for the bolt that serves to also fasten the forward-port corner of the chrome decorative head cover into place. However, you really can't put said cover into place until you are have torqued

all of the head cover bolts, since said cover, when installed, prevents access to some of said bolts. And, if you think you can just install the bolt that corresponds to location #12 later, you may find yourself faced with an oil leak, as the head cover sealant may set up a little too thick in that particular location (DAMHIK!).

Here is what I used to take the place of the decorative head cover - a stack of washers:

I just placed a bunch of washers on the bolt. This allowed me to torque the bolt down properly.

After the gasket sealant used on the head cover was cured, I removed the washers and installed the left decorative chrome head cover.

If anybody can improve on this, please take this opportunity to speak your piece now.....I welcome it!IHTH!