Hey all! Lot's of talk about can't get the carb screws out. Well, I bought a rigid screw extractor kit for $4 (on sale) at Harbor Freight (a lot of their stuff is junk, stuff like this is okay, though). I've used it many many times, and it has never failed me.

First of all, I had to remove a screw that was stripped, from this bike:

1975 Yamaha RD 350b.

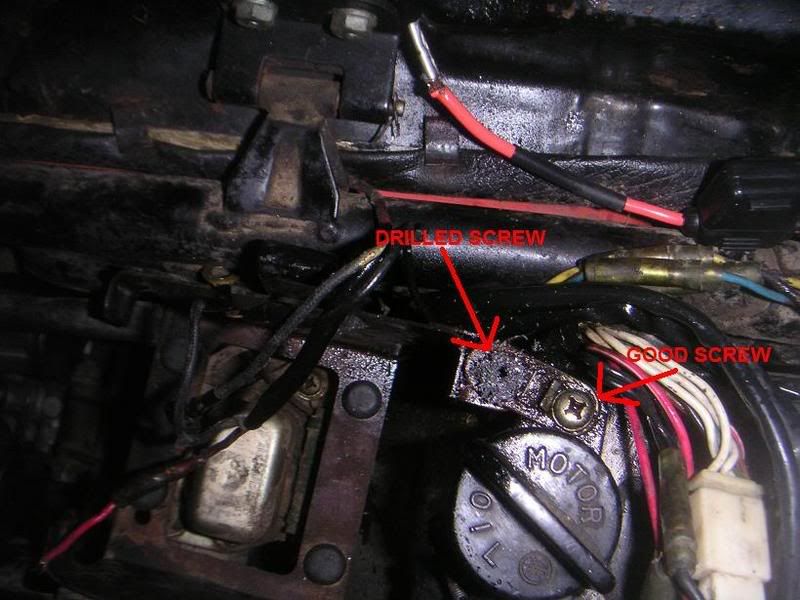

Here is a photo of the stripped screw:

I have already sprayed it with

PB Blaster. It's a "penetrating fluid." It gets in there and helps loosen bolts, screws, rusted stuff...

These are the tools I used, not counting a pair of vice grips:

Extractor kit:

1) So, take your center punch, and put a little divit in the

center of the stripped screw head. (no pic) It is important to get it as close to the center as possible.

2) Drill out the screw using the smallest drill bit first. I usually go right to the second size right away as the smallest size extractor almost never works.

Note on drilling: While you should press pretty hard, don't press hard enough to bend and snap the bit. You should also occasionally remove the bit whiel it is still spinning to break any metal "chips" in there. This applies to pretty much any time you drill metal. If you stop drilling w/ the bit still in the hole, it may be difficult to remove. Simply start drilling again and remove.

3) Take the second smallest (well, whatever size is appropriate, really) extractor and put it in the hole you've just drilled. The spiraled end should point into the screw. (Guess I forgot to take this pic... maybe later.)

4) Whack it w/ a hammer to seat the extractor. Whack it good... but keep it centered over the screw. Don't whack your fingers, or other parts of the bike.

5) Apply vice grips to the square end of the extractor and turn to remove the screw as you normally would (assuming it is a

"right handed screw"... this kit is right handed, so it only works on "normal, right handed screws"), as indicated. I heard the little "POP" it made when it came loose. Still had to use the VGs until it was finger loose.

6) Get another pair of pliers, grab the stripped screw which will still be on the extractor, and turn them as if the extractor were a screw, and you wanted to tighten it into the stripped screw. This action will dislodge the extractor from the stripped screw. Put away your tools (for now). You are done.

One note, though. If, while you are applying the vice grips, the extractor slips inside the drilled out screw, no big deal. Apply more hammer, and maybe the next size drill bit and extractor. Once, I had to hammer while a pal turned... It came out. Total time for this is about 10 minutes once you've done it a couple of times.

I'd also like to say (type) that I didn't know how to use this tool when I bought it. I had to call my pops, a Matco Tools dealer, and ask him since it wasn't obvious to me by looking at it (but it prolly should have been; I'm not too bright...

). Anywya, I hope this helps someone.

V